SXGM-A-3-11 layer Multifunction Blown Film production line

Thickness gauge system

The dielectric characteristics of the measured film produce a signal variation proportionalto the film thickness. The capacitive sensor is mounted in the centre of the beam,the oscillatory rotation system allows for the rotation of the sensor around the bubble, reading the angular position and allowing the generation of a circumferential profileof the thickness over 360°

Batch Blender

EASYBATCH is a traditional gain-in-weight batch blender, designed to dose and blendmultiple components in sequence for all processes where constant gravimetric feedingand an homogeneous mix is required.

Automatic air ring

TYPHOON3, is the cooling ring designed for maximum coolingcapacity, productivity, bubble stability, accurate thicknessprofile control and film quality. Typhoon3 represents a trueevolutionary step of the cooling ring, justifying the ambitiousexpression ‘cubed’.

Brief introduction:

Scope of application and characteristics Based on years of experience in designing plastic machinery and combining the material processing characteristics and rheological principles, we has developed a highly intelligent multi-layer co-extrusion PE film production line through continuous technological innovation, which is mainly applicable to daily necessities packaging, PE heat-shrinkable film, PE composite substrate film, etc. The equipment has good applicability to raw materials and can meet the user's demand for high quality and high capacity of film products.

The main technical parameters:

- Mechanical roll width: 1200-3200mm

- Maximum width of product: 1000-30000mm

- Product thickness: 0.02-0.15mm (conventional)

- When the thickness ≥ 0.12mm, the width decreases accordingly

- Thickness deviation (2sigma):

- (with automatic air ring online thickness measurement system)

- 0.04-0.049mm≤±6%

- 0.05-0.015mm≤±4%

- Three-layer co-extrusion structure: A/B/C

- Applicable raw materials: LDPE LLDPE/LDPE mLLDPE HDPE EVA, etc.

- Maximum output (IBC+refrigeration): 800kg/h

- The actual output is mainly related to the die size, formula and product specifications

Main Technical Data

| Max layflat width | 1200 - 32300 mm |

| Film thickness | 0.02 - 0.15 mm |

| Output | 150 - 800 kg/h |

| Material | LDPE/LLDPE/HDPE/EVA/EAA/mLLDPE |

| Rotary way | 360degre horizontal swing rotary |

| Total power | 240 - 360KW |

| Overall size ( L*W*H) | 11750*5500*9700mm |

Other Products

Printing equipment supporting series

High temperature resistant silicone sheet 3-6mm

Transmittance Haze Tester

SA-200-300 Dry Laminating Machine

GZR-500-1300 Express Courier Bag Making Machine (Automatic binding)

BGJ-500 High Speeb Checking and Rewinding Machine

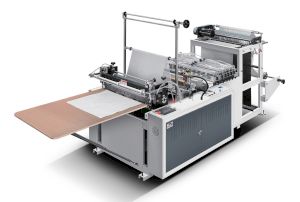

HOT SEALING COLD CUTTING BAGMAKING MACHINE

SJPL-G Plastic Tape Stretching Line

English

English ภาษาไทย

ภาษาไทย